Well-known automotive customers have relied on precision turned parts by Tränkle Turning Technology for years. There are numerous reasons for this, but more than anything it is our years of experience in the industry, maximum flexibility and high-performance machinery that provide the foundation for excellent quality – which we demonstrate on a day-to-day basis, also in the case of large series and volumes. Added to this are our high cost-effectiveness and 100 per cent delivery performance, factors that are of crucial importance in the automotive sector.

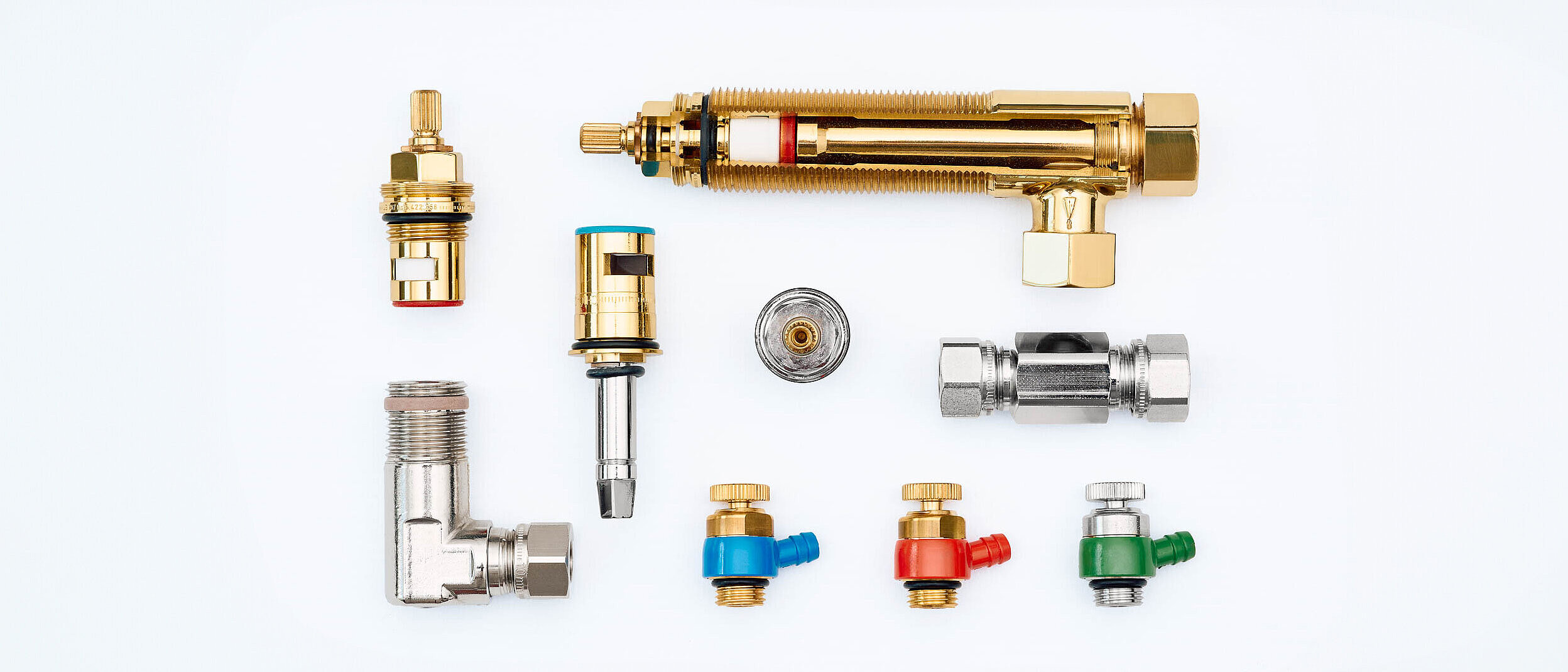

Product overview

Vehicle solutions that can be relied on

Our standardised process is based on the zero-defect principle. This guarantees optimum results: starting with sampling, documentation and cost-effective series production and also including (on request) 100% monitoring and customised logistics tailored to customer needs.

We’re more than happy to support you early on in the development process to enable you to draw on our specialist expertise in a way that is effective and profitable way for you.

- Sensor housings

- Screw connections

- Connecting elements

- Clamp rings

- Plug-in systems

- Thermal management components for all types of drive

- Components for truck compressor units

- Valve flaps

About us

Precision to perfection

Product type

Socket for thermal management component

Material

AlSiSn1MgBi (ENAW-6023 T6)

Machine type

Sliding headstock lathes

Cycle time

47 sec

Contact

We’re happy to help

Sales International

Daniel Heizmann

Tel.: +49 7722 862-121

Sales National

Christian Armbruster

Tel.: +49 7722 862-125