The sanitary sector has been using precision turned parts and valves by Tränkle Turning Technology for decades. The requirements for sanitary components are rigorous and varied: not only do they have to comply with strict drinking water regulations, they must also withstand mechanical stress and the effects of water and temperature.

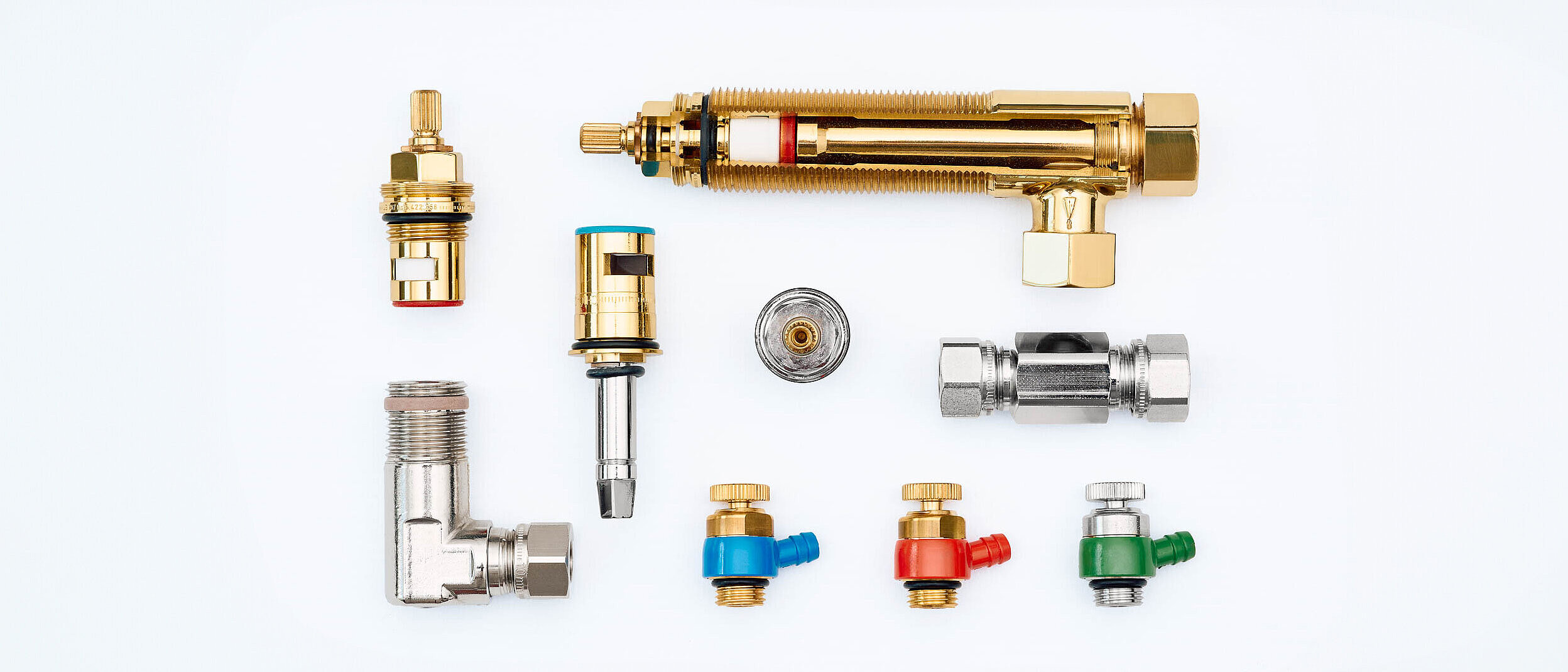

Product overview

Accuracy that stands out

We are your reliable partner when it comes to handling low-lead or lead-free drinking water alloys. In addition to technical precision components, we also manufacture visible components that meet the highest optical requirements - from galvannealed to polished and galvanised. At Tränkle, you receive the entire range of services from a single source, naturally in our excellent quality. To prevent stress corrosion cracking, for example, we rely on our many years of technical expertise, which includes careful selection of suitable materials, optimised production processes and, if necessary, thermal post-treatment.

- Fittings

- Nuts

- Valve housings

- Threaded nipples and hose connections

- Spindles

- Screw connections and adapters

- Fitting components

- Chrome-plated and polished visible parts

Example product

Precision to perfection

Product type

Lever for sanitary fitting

Material

CuZn39Pb3 (CW614N)

Machine type

Multi-spindle machine

Cycle time

3,5 sec

Contact

We’re happy to help

Sales International

Daniel Heizmann

Tel.: +49 7722 862-121

Sales National

Christian Armbruster

Tel.: +49 7722 862-125